ProductsDetails

Accessories

There are a wide variety of filter press accessories, and different types and uses of filter presses may employ different accessories. The following is an introduction to some common filter press accessories:

Filter Plates: They are the key components for the filter press to achieve solid-liquid separation. Common materials include polypropylene, polyethylene, cast iron, stainless steel, etc. Polypropylene filter plates are widely used due to their strong corrosion resistance, light weight, and low cost. Cast iron and stainless steel filter plates are suitable for scenarios where high strength and wear resistance are required. The surface of the filter plates usually has special patterns or grooves to guide the flow of the filtrate and increase the filtration area.

Filter Cloth: As a filtering medium, it comes into direct contact with the materials and plays a role in intercepting solid particles and allowing the liquid to pass through. The materials include polyester, nylon, polypropylene, etc. Filter cloths of different materials have different filtration performances and application scopes. For example, polyester filter cloth has high strength and good wear resistance, and is suitable for general industrial filtration; nylon filter cloth has good acid and alkali resistance and is often used for filtration in the chemical industry.

Accessories of the Hydraulic System: These include hydraulic pumps, hydraulic cylinders, hydraulic valves, hydraulic oil pipes, hydraulic oil, etc. The hydraulic pump provides power for the hydraulic system, pressurizes the hydraulic oil and transports it to the hydraulic cylinder. The hydraulic cylinder pushes the pressing plate through the pressure of the hydraulic oil to achieve the pressing and releasing of the filter plates. The hydraulic valves are used to control the flow direction, pressure, and flow rate of the hydraulic oil to ensure the stable operation of the hydraulic system.

Accessories of the Electrical Control System: Such as Programmable Logic Controllers (PLCs), touch screens, sensors, relays, contactors, wires and cables, etc. The PLC is the core of the electrical control system and is responsible for the automatic control of the operation process of the filter press. The touch screen is used for the interaction between the operator and the equipment, setting parameters and monitoring the operation status. The sensors monitor various parameters of the equipment in real time, such as pressure, temperature, position, etc., and feed the data back to the PLC.

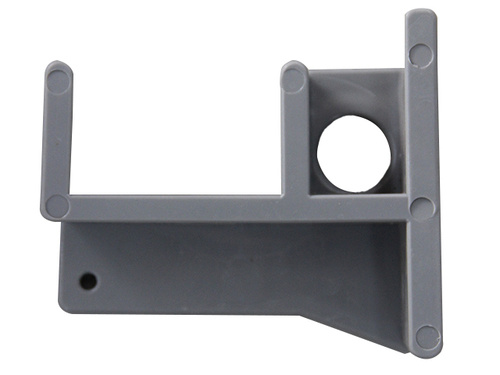

Filter Plate Handles and Plate Pulling Carts: The filter plate handles are used for manual handling and installation of the filter plates, making the operation convenient. The plate pulling cart is an important part of the automatic plate pulling system. During the cake discharge process, the plate pulling cart is driven by a motor to pull the filter plates one by one, realizing the automatic cake discharge.

Feeding Devices: These include feeding pumps, feeding pipes, feeding valves, etc. The feeding pump transports the materials to be filtered into the filter chambers of the filter press. Common feeding pumps include diaphragm pumps, centrifugal pumps, etc. The feeding pipes and valves are used to control the flow direction and flow rate of the materials to ensure that the materials can enter the filter chambers evenly.

Accessories of the Cleaning Device: Such as cleaning nozzles, cleaning pipes, cleaning pumps, etc. After the filtration is completed, the cleaning device is used to clean the filter cloth to restore its filtration performance. The cleaning nozzles spray high-pressure water onto the surface of the filter cloth to wash away the impurities attached to the filter cloth. The cleaning pump provides the pressure and flow rate required for cleaning.

Sealing Parts: Such as sealing rings, sealing gaskets, etc., which are used to ensure the sealing performance between the filter plates and at the joints of various components to prevent the filtrate from leaking. Common materials for sealing parts include rubber, silicone, etc., which have good elasticity and sealing performance.

Filter Plate Support Beams and Guide Rails: The filter plate support beams are used to support the filter plates and ensure the stability of the filter plates during the working process. The guide rails provide guidance for the operation of the plate pulling cart to ensure that the plate pulling cart can accurately pull open and close the filter plates.

Recommended News

Recommended News

-

Master These Tips, Easily Solve Common Faults of Diaphragm Filter Press Plates

2025-04-28 12:03:11

-

Unveiling Methods to Prolong the Service Life of Diaphragm Filter Press Filter Plates

2025-04-26 09:51:45

-

Key Points of Routine Maintenance for Diaphragm Filter Press Filter Plates

2025-04-25 05:13:34

-

What Are the Advantages of Highly Elastic Diaphragm Filter Plates in Filter Presses?

2025-04-24 03:04:12

-

Do you know about the diaphragm filter plate of a filter press with high-efficiency filtration capabi

2025-04-23 12:18:11

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:http://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province