ProductsDetails

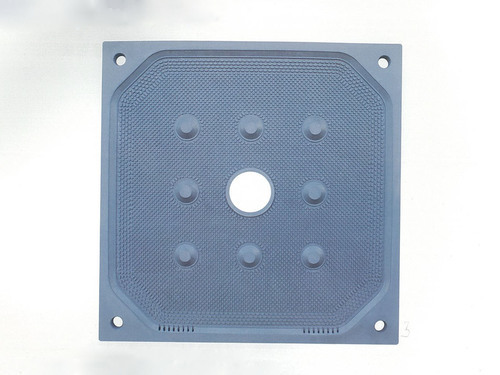

1250 Polypropylene Chamber Filter Plate

The Type 1250 polypropylene chamber filter plate is a key component for filter presses to achieve efficient solid-liquid separation and plays a vital role in the filtration processes of numerous industrial productions. The model number "1250" usually represents the specific size specifications of the filter plate. This filter plate is meticulously manufactured from high-quality polypropylene materials. With its outstanding performance, it is widely applied in filter press equipment across multiple industries such as chemical engineering, environmental protection, food, and pharmaceuticals, providing reliable and efficient solutions for the filtration of various materials and assisting enterprises in achieving the goal of solid-liquid separation during the production process.

Product Structural Features

Dimension Specifications: The external dimensions of this filter plate are generally about 1250×1250mm, and the thickness usually ranges from 70mm to 90mm. The specific thickness will be adjusted according to the actual design requirements and usage scenarios. The diameter of the central feeding hole is precisely designed to ensure that the materials can smoothly enter the filter chamber. Its reasonable size configuration guarantees the stability and uniformity of the feeding. Such a size design endows the filter plate with a suitable filtration area and filter chamber volume, which can fully meet the filtration needs of productions of different scales and effectively improve the filtration efficiency.

Chamber Structure Design: The filter plate has a typical chamber structure. Sealing grooves are provided around it, allowing for the precise installation of sealing rubber strips. During the operation of the filter press, adjacent filter plates fit closely together, and the sealing rubber strips play a crucial role in forming a filter chamber with excellent sealing performance. This effectively prevents the leakage of filtrate and ensures the smooth progress of the filtration process. The surface of the filter plate is carefully designed with drainage grooves, which have a unique shape and layout. These grooves can guide the filtrate to flow smoothly out of the filter cloth and be quickly discharged from the filter chamber through the drainage holes on the filter plate, ensuring the smoothness of the entire filtration process.

Reinforcing Rib Design: In order to significantly enhance the strength and rigidity of the filter plate during the filtration process, enabling it to withstand a large pressure without deforming or cracking, reasonably arranged reinforcing ribs are set on the surface or inside of the filter plate. These reinforcing ribs adopt a special design and arrangement method, which can effectively disperse the pressure and distribute it evenly across all parts of the filter plate. This ensures that the filter plate maintains stable and reliable performance during long-term use and extends the service life of the filter plate.

Recommended News

Recommended News

-

Master These Tips, Easily Solve Common Faults of Diaphragm Filter Press Plates

2025-04-28 12:03:11

-

Unveiling Methods to Prolong the Service Life of Diaphragm Filter Press Filter Plates

2025-04-26 09:51:45

-

Key Points of Routine Maintenance for Diaphragm Filter Press Filter Plates

2025-04-25 05:13:34

-

What Are the Advantages of Highly Elastic Diaphragm Filter Plates in Filter Presses?

2025-04-24 03:04:12

-

Do you know about the diaphragm filter plate of a filter press with high-efficiency filtration capabi

2025-04-23 12:18:11

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:http://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province