ProductsDetails

Energy-efficient High-speed Filter Press

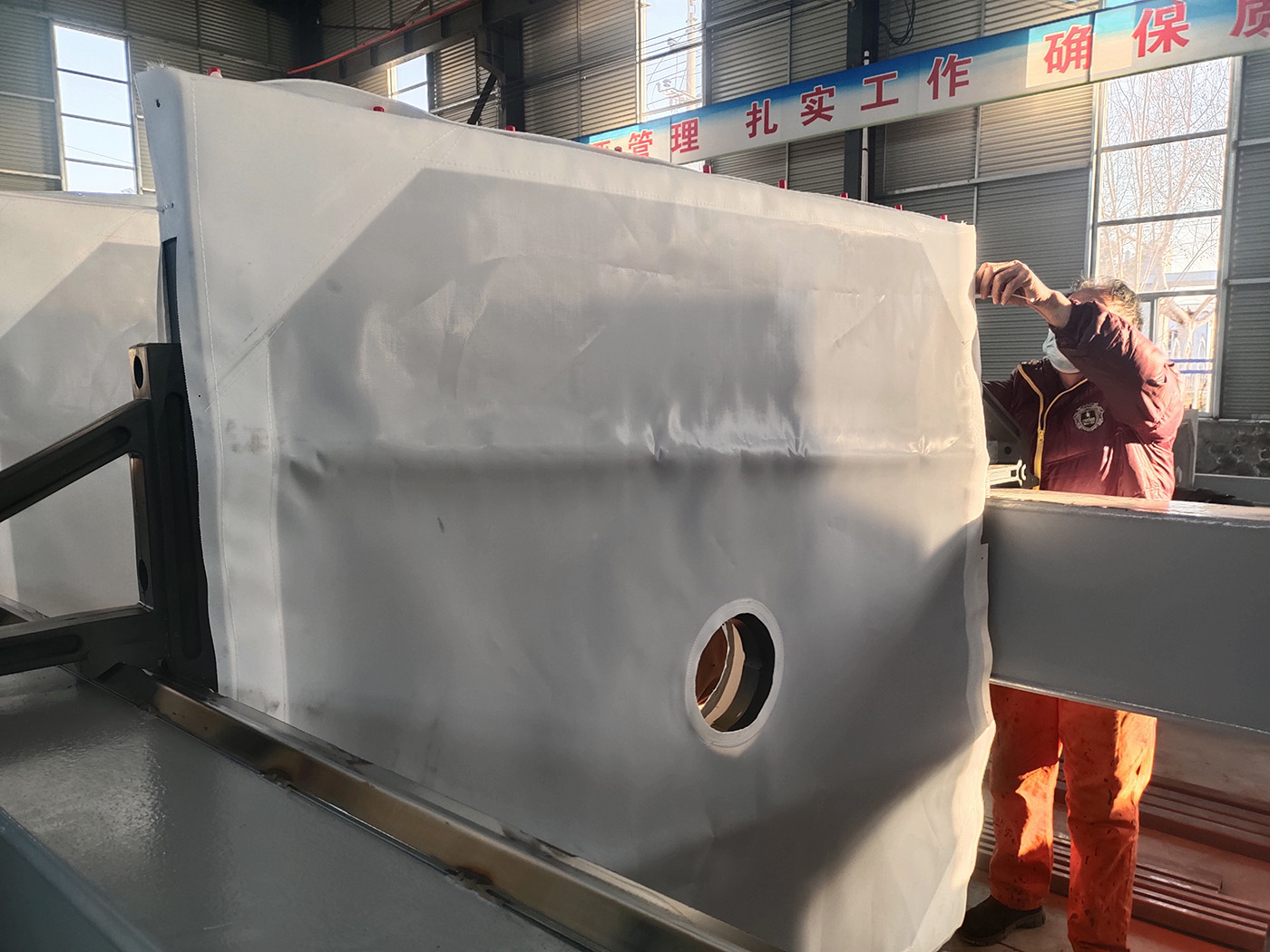

Energy-Saving and Environmentally Friendly Filter Press

The energy-saving and environmentally friendly filter press is known for its low manufacturing cost,compact size,simple structure,high production efficiency,stable and reliable operation,low maintenance cost,and wide applicability.It offers a large adjustable range in various aspects such as the number of feed inlets,discharge gap,plate pulling force,and pulling speed.Additionally,it can be customized or modified to any specification ranging from 100 to 1000㎡or more for fast filter presses(both chamber and diaphragm types).The machine's appearance and weight remain nearly the same as ordinary automatic filter presses of the same filtration area,and modifications do not require changes to the original equipment foundation.This allows for quick on-site installation,achieving significant improvements in economic benefits for users.

The filter press cloth washing cart, also known as the automatic filter cloth cleaning system or automatic filter press cleaning device, is a commonly used auxiliary device for filter presses. Its working principle involves using a PLC program-controlled motor servo drive system to automatically perform high-pressure washing of the filter cloth. This significantly improves filtration efficiency, enhances filtration effectiveness, extends the service life of the filter cloth, and reduces labor and manual workload, effectively solving the challenge of filter cloth cleaning in various industries using filter presses.

The filter press cloth washing cart primarily consists of six main components: the washing device travel beam, water inlet pipe, washing pipe, lifting device, travel mechanism, and limit control system.

Depending on the installation space available at the top of the filter press, there are two cleaning solutions: vertical washing and folding horizontal washing. Based on the viscosity of the material, options for medium-pressure and high-pressure cleaning are available. Additionally, for special operating conditions, customized designs can include separate washing with cold and hot water or separate washing with clean water and washing liquid.

The filter press cloth washing cart is widely used in various industries, including chemical and pharmaceutical filter presses, municipal wastewater filter presses, food and sugar processing filter presses, metallurgical wastewater filter presses, coal washing filter presses, and tailings dewatering filter presses.

Product Features

The modified fast filter press achieves more than six working cycles per hour,increasing the single-machine output by 1 to 1.5 times.Its performance far exceeds that of ordinary filter presses,three-stage fast-opening filter presses,program-controlled filter presses,and automatic filter presses.

Application Scope

The fast filter press is widely used in industries such as:

Coal washing and processing

Coal mine tailwater treatment

Alcohol feed production

Non-ferrous metal flotation

Fine rice flour production

Potato starch production

Bio-oil production

Industrial wastewater treatment and purification

Volatile liquid filtration

Fine chemical raw material filtration

Recommended News

Recommended News

-

Master These Tips, Easily Solve Common Faults of Diaphragm Filter Press Plates

2025-04-28 12:03:11

-

Unveiling Methods to Prolong the Service Life of Diaphragm Filter Press Filter Plates

2025-04-26 09:51:45

-

Key Points of Routine Maintenance for Diaphragm Filter Press Filter Plates

2025-04-25 05:13:34

-

What Are the Advantages of Highly Elastic Diaphragm Filter Plates in Filter Presses?

2025-04-24 03:04:12

-

Do you know about the diaphragm filter plate of a filter press with high-efficiency filtration capabi

2025-04-23 12:18:11

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:http://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province